The problem:

A global bakery supplier of liquid glaze and frosting was inconsistently filling 3 and 5 gallon pales of product. Because of variability in the product flow as plant temperatures increased after start up, the time-fill machine was overfilling the buckets by as much as 5% to ensure that minimum specifications weights were met. Additionally, lids were not always secure and bar code labels were sometimes missing.

The solution:

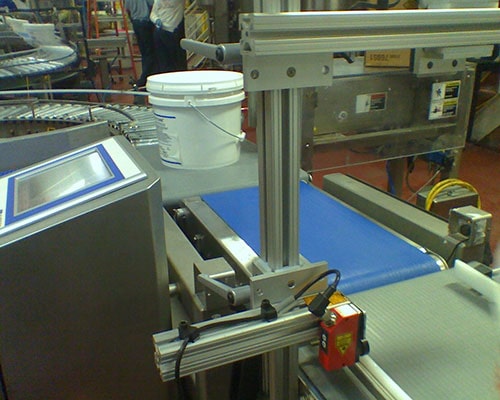

AP Dataweigh, Inc. designed a weighing, label detection and lid detection system that solved all of the above issues. Sensors and communication systems were installed in the scale controller to provide one control of the fill line.

The payback:

The 5% overfill was eliminated and the operators had reliable and instantaneous feedback of the operation of the filler, capper and labeler.

- Investment – ~$100,000

- Savings – ~$750,000/year

- Payback – 2 months

After a six month trial period, six additional lines were equipped with the system.

Have you considered how your plant environment is affecting your production line? Are your time-fillers really preserving your profits?

Time Filler vs. Checkweigher…… ACTUAL flow rate affected by temperature vs. Accurate WEIGHT no matter the temperature!….Include LABEL & LID detection all in one unit!…..Best rate of return on investment!