Increase the performance of your checkweigher with technical support and preventative maintenance from AP Dataweigh.

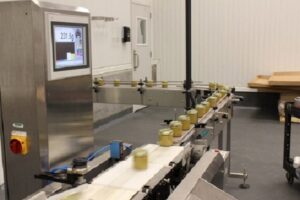

A crucial component in ensuring accurate and efficient production is the checkweigher—a vital tool for verifying the weight of packaged goods. At AP Dataweigh, Inc., we provide our clients with high-quality checkweighers and inspection equipment. However, knowing how to best use and maintain these machines is crucial to ensure they work well for many years. Adopting a proactive maintenance approach is essential to maximize the longevity and performance of your checkweigher. In this blog, we’ll explore practical tips for scheduling preventative maintenance, working with a manufacturer that provides reliable technical support, and emphasizing the significance of regular maintenance to avoid costly downtime.

Schedule Regular Preventative Maintenance

The adage “prevention is better than cure” holds true in the realm of checkweighers. Regular, scheduled maintenance is the cornerstone of ensuring your equipment operates optimally. Develop a comprehensive maintenance schedule that includes tasks such as:

- Calibration Checks: Regularly calibrate your checkweigher to maintain accuracy in weight measurements.

- Cleaning and Inspection: Keep your checkweigher clean from debris and contaminants. Regularly inspect belts, conveyors, and sensors for any signs of wear or damage.

- Software Updates: Stay abreast of software updates provided by the manufacturer to ensure your checkweigher benefits from the latest features and improvements.

Choose a Manufacturer with Robust Technical Support

When selecting a checkweigher manufacturer, prioritize those that offer robust technical support. A reliable manufacturer should provide the following:

- Training: Comprehensive training programs for your operators ensure they are well-versed in the day-to-day operation and basic troubleshooting of the checkweigher.

- Customer Support: Emergencies can happen at any time. Opt for a manufacturer with accessible customer support to address urgent issues promptly.

- Spare Parts: Manufacturers that can provide spare parts help reduce downtime caused by waiting for parts to be ordered or delivered by outside providers. Ordering parts from AP Dataweigh means you can streamline the repair process for your checkweigher.

Emphasize the Importance of Regular Maintenance

Highlighting the significance of regular maintenance within your organization is crucial. A well-maintained checkweigher contributes to:

- Consistent Product Quality: Regular maintenance ensures accurate weight measurements, contributing to consistent product quality and compliance with regulatory standards.

- Maximized Productivity: Avoid costly downtime by proactively addressing potential issues through scheduled maintenance, preventing disruptions to your production line.

- Extended Equipment Lifespan: A well-maintained checkweigher is more likely to have a longer lifespan, providing a better return on your investment.

In the world of manufacturing, the checkweigher is an indispensable tool for maintaining product quality and compliance. By adopting a proactive approach to maintenance, choosing a manufacturer with robust technical support, and emphasizing the importance of regular checkweigher upkeep, you can maximize its lifespan and keep your production line running smoothly. Investing time and resources in preventative measures today will undoubtedly pay dividends in the form of increased efficiency, reduced downtime, and prolonged equipment lifespan.

Contact AP Dataweigh, Inc. For Customized Checkweighing Solutions

Established in 1994, AP Dataweigh, Inc. is a checkweigher manufacturer offering a complete line of custom-built and dynamic checkweighers and inspection system solutions. Our American-made machines address the needs of the pharmaceutical, agricultural, food, and industrial product markets throughout North America. We manufacture our machines to exact customer specifications and design them to integrate into your production line. What distinguishes us from the competition? We make what customers need instead of trying to sell what we make.

To learn more about the products we can provide for your facility, contact us online or by phone at 678-679-8000. You can also follow us on Facebook, LinkedIn, Twitter, and YouTube for updates on our products and industry.