The problem:

Today’s automotive engines require tighter tolerances in component manufacturing. An industry leader in forging powdered metal connecting rods had an AP Dataweigh competitor’s scale transferring parts from a press to a processing robot. The scale was only accurate to +/- 1 gram and vibration and airflow around the scale resulted in the repeatability of the scale being +/- 3 grams on a 300 gram part. A substantial number of good parts were being rejected along with the bad parts resulting in 100% offlineweighing of all parts. Furthermore press operators could not properly set up the presses because of the variability in weight data, thereby perpetuating the problem.

The solution:

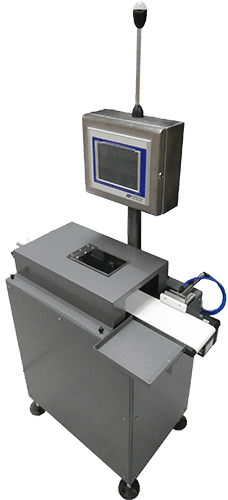

An AP Dataweigh, Inc. HR 1 series scale replaced a competitor’s scale. Because of the capabilities of its load cell and processor not only could the HR 1 scale weigh to +/-0 .1 grams, but surrounding vibrations could be filtered out. Variation due to airflow was also eliminated by fabricating a draft shield sized perfectly to the part and machine.

The payback:

Operators now had a tool to allow proper set up of their presses. Off line weighing was eliminated and one operator could now comfortably handle four presses, instead needing an operator on each press.

- Investment: – ~$100,000

- Savings – ~$200,000/year

- Payback – six months

Let AP Dataweigh, Inc. help evaluate the environmental factors that are negatively affecting your production lines. We build what YOU need to help run your plant leaner.Your system can decrease your raw materials consumption, which will decrease your rejection rate. Increase your productivity and profitability…the AP Dataweigh!

Too many rejects! Powdered metal forging…. Auto engine parts …..Competitor vs. AP Dataweigh……

Swiftly weigh tight tolerances!…Eliminate plant environment factors you may be overlooking…..Ensure maximum accuracy…..Reduce labor costs